Repairing

a too-deep slot in a Nut

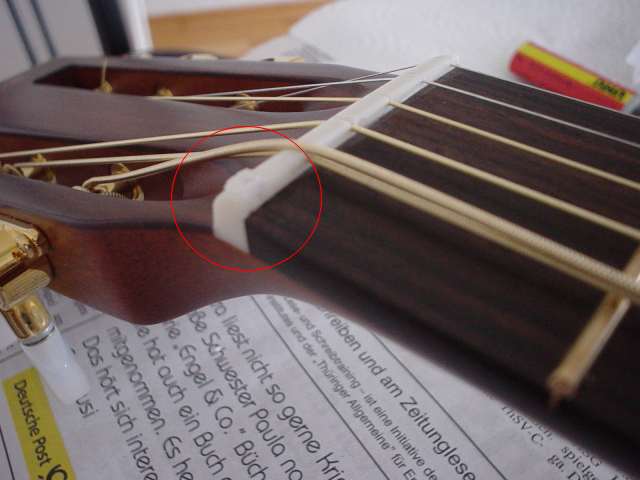

One opportunity would be to make a new nut (and by the way switch to bone). The other method I heard of would consist of filling the slot with a mixture of instant glue and baking soda. After that the slot can be cut new. That's what I did and here's the pictured story how it worked.

Then I cut back the tape using the razor blade.

Now the edge has to be removed. This I did utilizing the file of my old Leatherman tool. I painstakingly took care, not to mar or scratch any part of the neck or headplate.

The result: No more groove or slot for the low e string.

Now I had to saw a new e-string slot. With the thickest of my nut sawblades this was a quick task. The compound material of instant glue and soda is quite brittle. While sawing I avoided any contact of sawblade and headplate. Additionaly I moved the blade always keeping the angle to be seen on the picture below. The angle of the blade forms the same angle with the string's sides both left and right of the nut.

After having reached the proper depth I cleaned headplate and fretboard. The compound material seems to stand the string pressure well. Now the guitar is set up right, no more string buzz any longer.